The Ultimate Guide To 24??media

The Ultimate Guide To 24??media

Blog Article

The Buzz on 24??media

Table of ContentsThe Of 24??mediaAll About 24??mediaMore About 24??media24??media Can Be Fun For EveryoneAll About 24??media

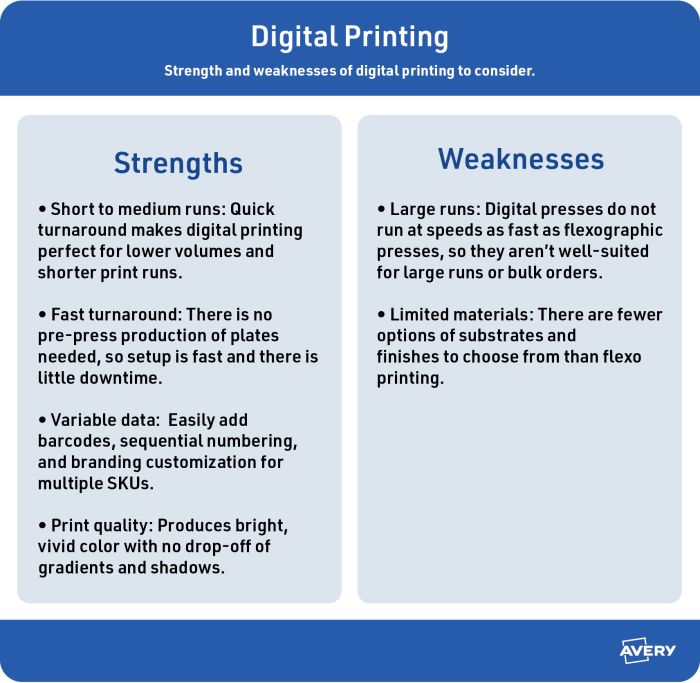

Advancements in print technology are transforming the communications playing field when it comes to high quality, price and innovative capabilities. Countered printing and digital printing are the significant processes by which print tasks are undertaken both making use of four-color printing methods. Each choice has its advantages, supplying different methods to satisfy the requirements of varied manufacturing projects.

Typically, this has actually been one of the most constant technique for specifically maintaining color matches, making it optimal for print runs that only need static printing such as pre-printed types, brochures, flyers, calling card, and mass postcard mailings. However, because of the static nature of litho printing, it is not suitable for variable print pieces that will certainly be mailed to individual receivers such as declarations, letters, and personalized postcards.

The 2-Minute Rule for 24??media

The newest developments in print technology are aiding to bring numerous of offset's benefits right into the digital printing world genuinely altering the face of modern printing! There are some vital distinctions between Offset Printing and Digital Printing.

Today's digital print equipment is among the most advanced on the marketplace. Here are a few of the greatest advantages of using digital printing: dominate the electronic print space, with full-color printing completed in one procedure and seamlessly published directly from a print data. Without an extensive set up procedure, the calibration time of a certain work is reduced, adding to quicker print time and general shipment.

The inkjet printing procedure has assisted to transform the sector as well as the quality and rate of the output. The latest inkjet innovation can publish on standard countered stocks with dull, silk, and glossy coatings. High-grade digital print coupled with software-managed shade administration practices includes optimum value to publish items and makes production procedures extra reliable than countered.

Getting The 24??media To Work

(https://zenwriting.net/za24media/digital-printing-crafting-experiences-not-just-products)

Environmentally friendly and eco-friendly inks and printer toners are likewise offered for more sustainable printing. Digital print additionally removes the requirement to clean plates or blankets with dangerous chemicals at the end of the printing procedure.

Variable data helps services reach their precise clients and audience with uniquely-created and customized content. As technology boosts, the high quality of electronic printing has come to be second-to-none, with greater detail, color match abilities and overall accuracy. Without the demand to wash plates or use excess ink, electronic printing is also less wasteful and typically much more environmentally friendly.

("flexo"), involve numerous make-ready actions to move an initial picture to a substrate.

The Buzz on 24??media

While digital printing is a practical choice for most short-run print jobsunique celebrations, prototyping, or other considerationsits contemporary abilities actually show in rapid turn-arounds. Being able to tailor packaging via variable information printing has opened up brand-new possibilities for you to involve with your clients in even more tailored ways. Digital printing, with fewer moving items, is extra active than offset hereof.

It's a means to blend your packaging and advertising and marketing techniques. Decreased set-up time saves money on the front end. And given that these are not enormous bulk orders, smaller sized businesses can afford to publish without having to fulfill the greater and more pricey print thresholds of traditional printing. Digital printing aids secure your brand against counterfeiting by integrating overt and concealed options on your packaging.

Make certain you team up with a printing and product packaging companion that has the best qualifications. While eleventh-hour printing and customization are a big advantage, electronic may not always be the very best method for you. As an example, balance out printing has the advantage of cost-effectiveness with big print runs, particularly those with advanced ornamental effects and specialty coatings.

Some Known Facts About 24??media.

Lithographic presses check out this site utilize two print platesa positive and a negativeto transfer high-quality color graphics onto a suitable substratum. The positive plate, with its smooth surface area, brings in oil-based inks and repels water. In comparison, the unfavorable plate, with its harsh appearance, soaks up water and pushes back oil. Rubber rollers are then utilized to transfer the picture from home plate to the corrugated surface.

Corrugated paper can often verify to be a tough surface to publish on, yet Litho prints to a different surface and is then laminated to it, making it easy to publish premium pictures. It can be very consistent, also for long terms. The more you print, the less costly the prices end up being for Litho.

What Litho does not provide you is exactly what Digital does, modification. Pricey set up Longer turnaround No Variable Data Printing Smaller sized shade gamut, shades can be less brilliant Digital printing is the procedure of printing electronic images straight onto the corrugated substrate utilizing a single-pass, direct-to-corrugate technique.

Report this page